Nowadays, we have plenty of tools to control the quality of concrete. But how do you choose the right one for your specific needs and requirements? In this blog, we’ll discuss key features you should be looking for in an effective quality control software connected to the batch control system.

Quality control of the concrete mixing process and the concrete itself is an integral part of each concrete producer’s everyday life. Proper quality control allows tracing concrete batches and ensures that production complies with the actual standards. It is also essential for ensuring the safety of concrete for construction projects.

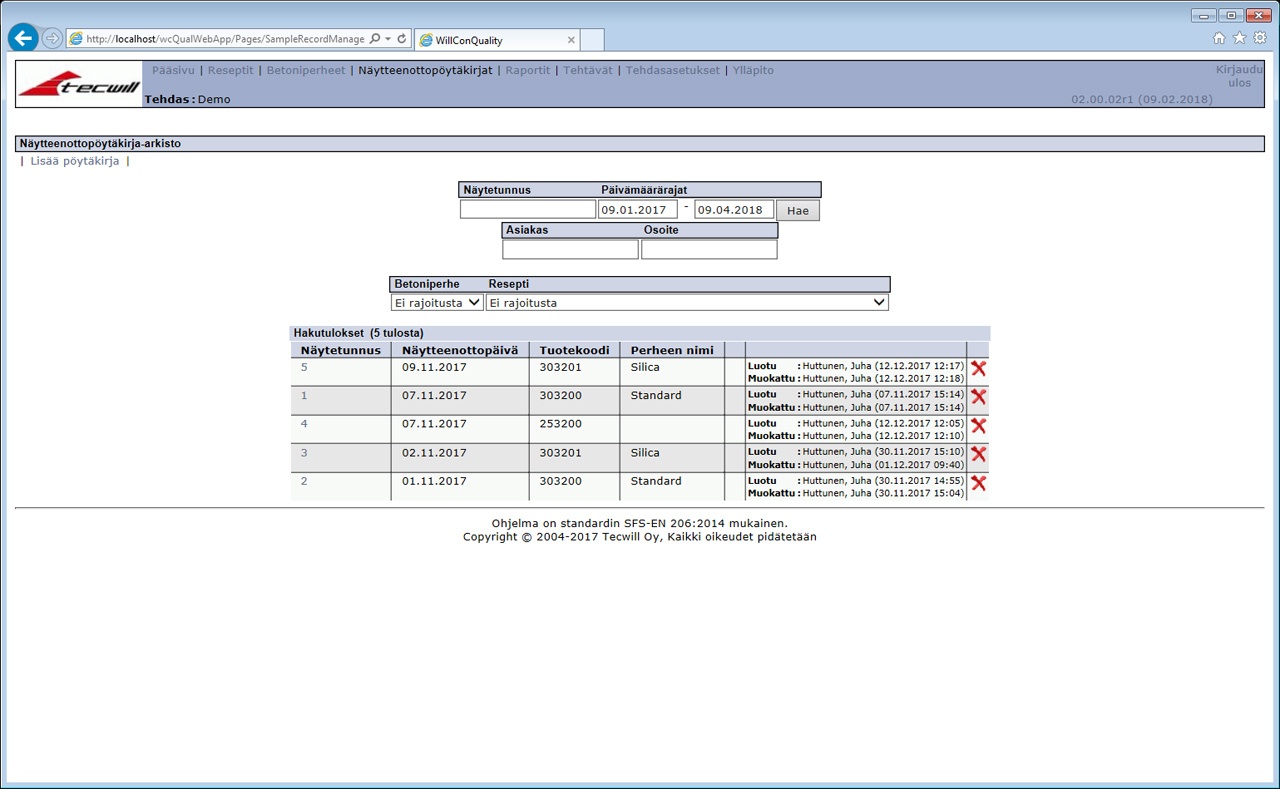

At a concrete batch plant, the standard procedure for quality control is to take concrete samples. Whenever samples are taken, the data is recorded by the quality control system. Fresh concrete samples are used for measurements of the temperature, the air content and slump. Hardened concrete in a cylindrical or cube shape is used for compressive strength tests.

To ensure the quality of certain concrete mix designs, additional quality control methods are often necessary. For example, self-consolidated concrete may require several tests. These include J-Ring, slump flow and even the U-Box or L-Box concrete tests for product development or prequalification.

There are numerous control software options to facilitate this process on the market today. These range from those based on Excel files requiring manual data entry to advanced versions that can automatically gather extensive data on concrete production. Below are the four most important features of high-grade concrete quality control software.

1. Automation

An intelligent concrete quality assurance system automatically transfers information from the batch control system to the software.

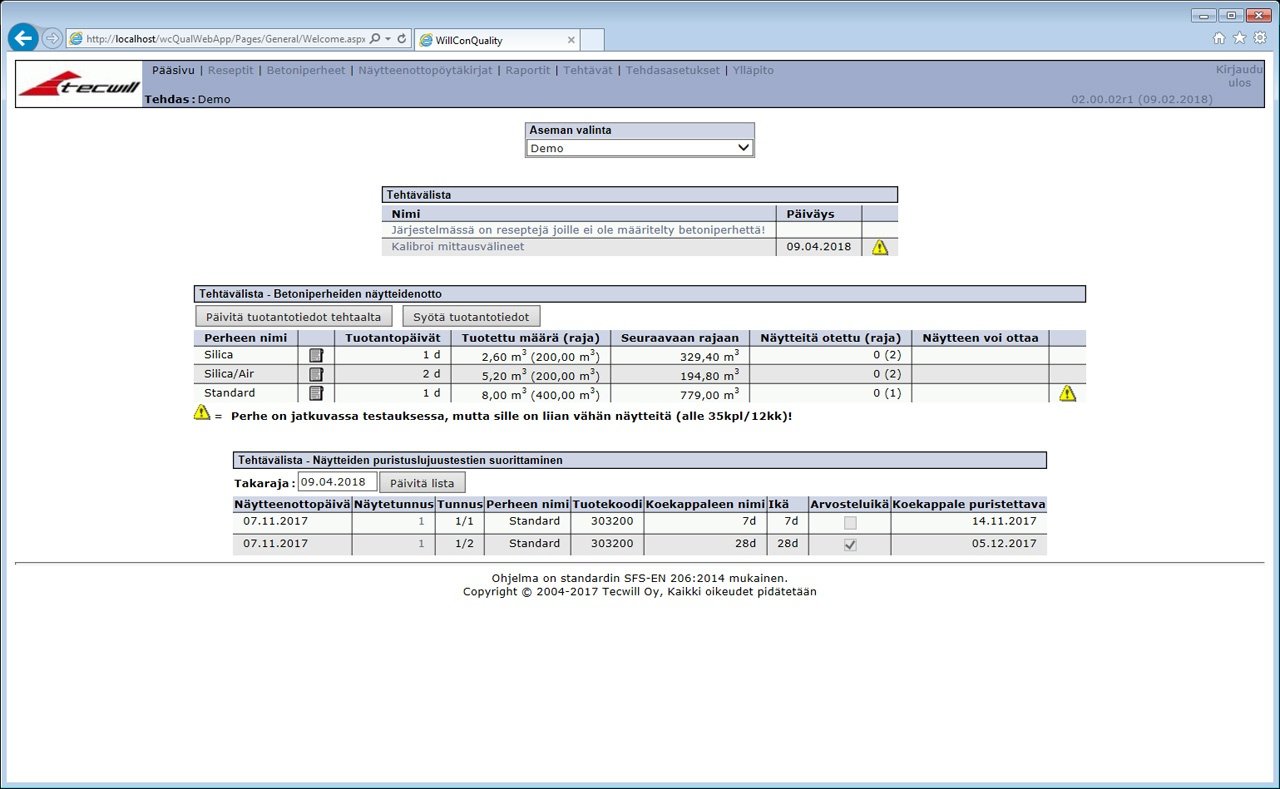

The broader the spectrum of imported data, the more functions can be automated. For instance, by integrating the production volumes of each mix design, the system can automatically monitor the number of required samples. It also ensures timely alerts for concrete sample collection.

Effective quality control software should also seamlessly integrate with other control systems and concrete mixing plants. This further improves efficiency, minimizes manual work and allows continuous data monitoring, mitigating the risk of errors.

2. Task lists

A smart quality assurance system is able to automatically generate reliable task lists for users – in this case, plant operators. Then, they don’t have to keep every aspect of quality control in mind. The software takes care of timely reminders.

Once a report is started for a concrete sample with the initial measurement data, the system then issues reminders based on elapsed time. For instance: “It is now X days since sample Y was taken; it’s time to perform a compressive strength test for this sample.”

3. Reports

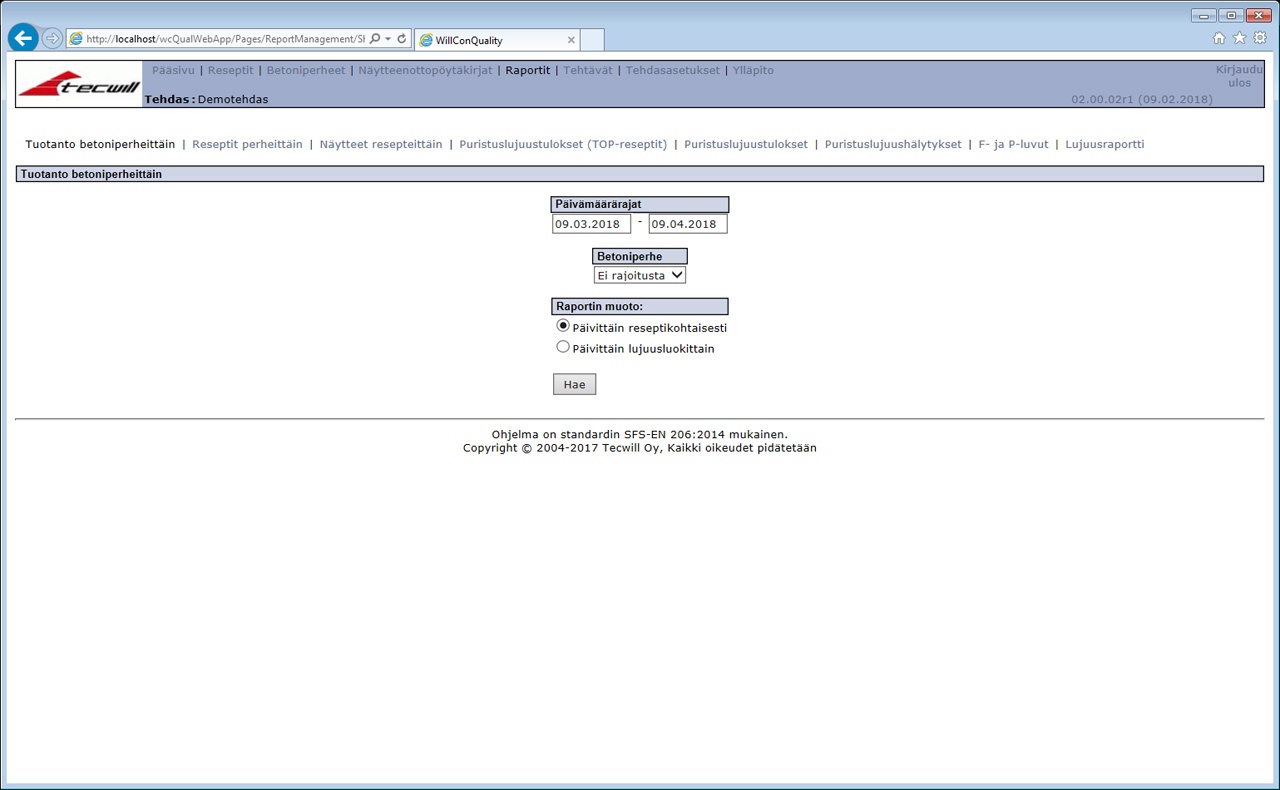

Tens or even hundreds of samples are taken at each concrete factory yearly. Therefore, producing reports from data entered into the system is one of the most important features of a good concrete quality control software.

Reporting ensures users have all the essential information available at a glance and can easily track and analyze developments.

Reports can encompass a compilation of recipes used in different samples, along with their measurements and test results. They may also include graphs reflecting the variation in compressive strength within a certain period. With this kind of report at hand, the user can monitor changes proactively.

The reports may come in various formats, ranging from traditional PDF and Excel files to graphical formats. Regardless of the format, they must be easy to handle and share with others.

4. Seamless integration

Manual consolidation of data from diverse systems is a time-consuming process that can cause headaches. Therefore, different concrete quality control functions should be automatically combined within a single system.

Here, a user-friendly interface for quality control software is crucial. It has to be easy to manage information from the control systems of different manufacturers.

Tecwill offers a comprehensive control system and quality control software. It is specifically designed for both ready-mix concrete plants and plants for precast concrete elements, blocks and pavers.

Do you want to learn more about Tecwill’s concrete quality control software and its benefits?